Cigar Collections

Home » Cigar Collections

Cayman cigar’s are created from a variety of premium Cuban seed, whole leaf tobaccos, sourced from esteemed growing regions such as Nicaragua, Dominican Republic and the Caribbean.

We strongly support family farms and growers who are as passionate about quality as we are. We invite you to explore our portfolio of fine luxury cigars.

-

2 Cigar Case

$80.00 Select options -

Sale!

Caravel

$60.00 – $240.00 Select options -

Sale!

The Mariner Robusto

$78.00 – $295.00 Select options -

Cayman Collection

$148.00 – $295.00 Select options -

Sale!

Sovereign No. 1 Robusto

$78.00 – $295.00 Select options -

Sovereign No. 1 Corona

$55.00 Select options -

Sale!

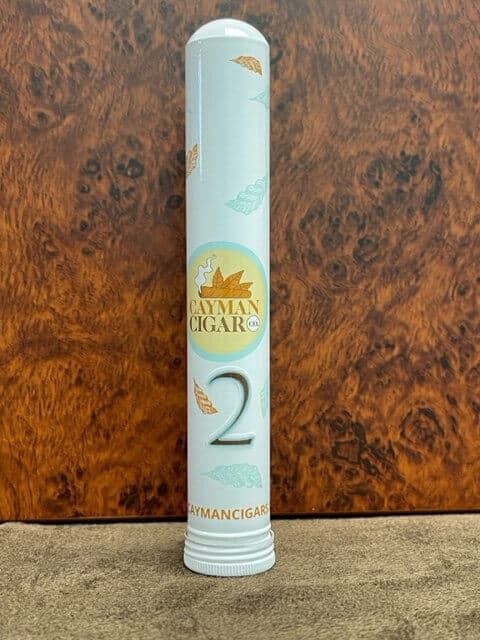

Sovereign No. 2 Robusto

$78.00 – $295.00 Select options -

Sovereign No. 2 Corona

$55.00 Select options -

Sale!

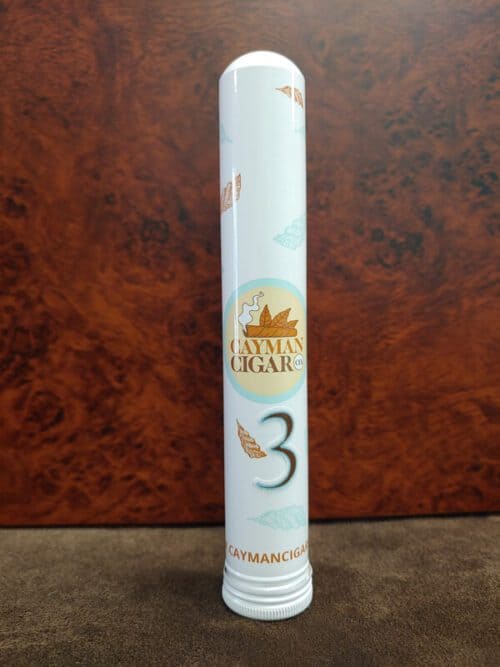

Sovereign No. 3 Robusto

$78.00 – $295.00 Select options -

Sovereign No. 3 Corona

$55.00 Select options -

Sale!

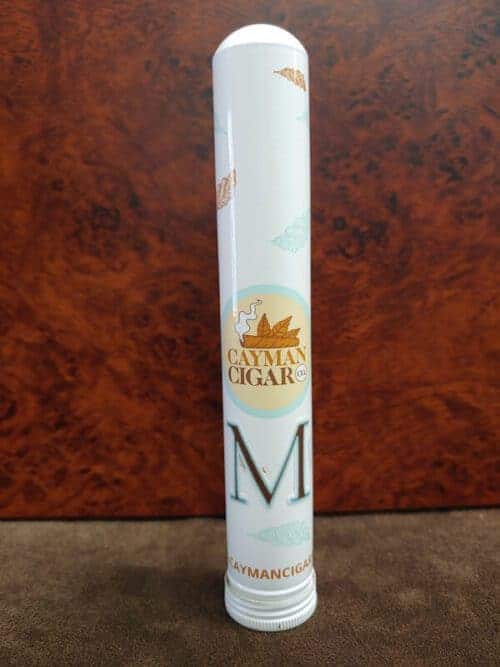

Monarch Robusto

$78.00 – $295.00 Select options -

Monarch Corona

$55.00 Select options